Hidden Frame Curtain Wall

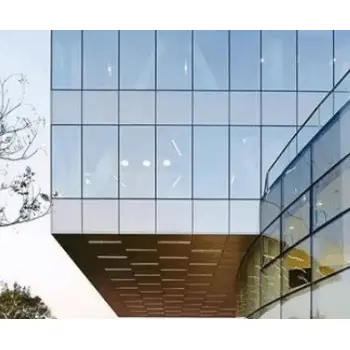

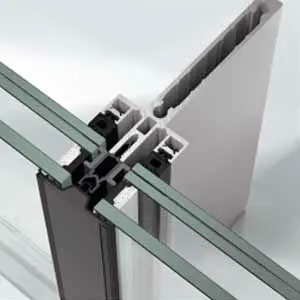

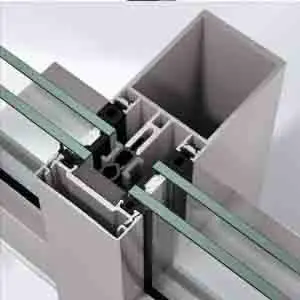

As the core supporting structure of hidden-frame glass curtain walls, the design and performance of hidden-frame curtain wall profiles directly affect the safety, aesthetics and durability of the curtain wall.

No Exposed Frame

Hidden-frame curtain wall profiles fix the glass through structures hidden behind the glass (such as aluminum alloy profile frames, sealant joints, etc.). From the outside, the profile frames are almost invisible, only the glass panels and sealant joints can be seen, achieving a “panoramic” visual effect and greatly enhancing the transparency and modernity of the building.

Force Concealment

The force-bearing points of the profiles (such as the connection between the glass and the profiles, and the fixation of the profiles to the main structure) are all hidden on the inner side of the glass or inside the structure. It is necessary to ensure stability through precise mechanical calculations to avoid affecting the appearance or force imbalance due to exposed components.

Work in Harmony With Sealant

The groove design of the profile should provide sufficient bonding area for the structural adhesive (the adhesive width is usually ≥7mm) to ensure that the glass and the profile are firmly bonded through the adhesive joint. Meanwhile, the surface of the profile needs to undergo special treatment (such as chemical cleaning) to enhance compatibility with the adhesive and prevent the adhesive joint from falling off and causing water leakage.

The core feature of hidden-frame curtain wall profiles is “precision in concealment, safety in beauty”. Their design needs to balance mechanical properties, sealing performance, weather resistance and visual effect. They are widely used in high-end commercial buildings, office buildings, landmark buildings and other scenarios with high requirements for appearance and transparency. However, at the same time, its construction is difficult and costly, and the requirements for the quality of profiles, installation techniques and later maintenance are also stricter.

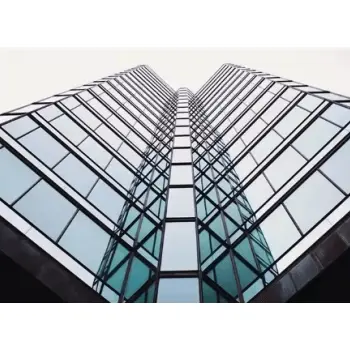

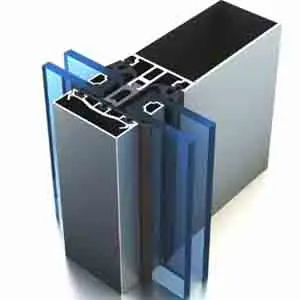

Frame Curtain Wall

Frame curtain walls are non-structural outer coverings for buildings, featuring a visible framework that supports glass or other panels. Composed of aluminum, steel, or composite materials, the frame forms a rigid grid, with vertical mullions and horizontal transoms bearing loads like wind pressure and self-weight.

These systems balance aesthetics and functionality. The exposed frame adds architectural definition, while allowing customization in grid patterns. Panels, often insulated glass or metal, enhance energy efficiency and weather resistance.

Installation involves attaching the frame to the building’s structure, ensuring flexibility for thermal expansion. They suit various designs, from modern to traditional, offering durability and low maintenance. Widely used in commercial and high-rise buildings, frame curtain walls merge structural integrity with transparent, light-filled spaces.

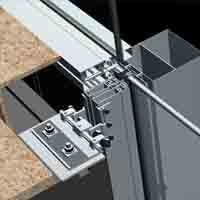

As the core supporting component of exposed frame glass curtain walls, the characteristics of exposed frame curtain wall profiles are mainly reflected in multiple aspects such as structural visibility, force stability, and adaptability, as detailed below

The Frame Clearly Exposed

Profiles (including vertical columns and horizontal beams) are directly exposed on the surface of the curtain wall, forming a clear grid-like frame. Glass panels are inlaid within the frame, and the lines and shapes of the profiles can be intuitively seen from the building’s exterior, becoming part of the building’s facade design.

Decorative Effect

The surface of the profiles can be treated through processes such as anodizing, powder coating, and fluorocarbon coating, presenting a variety of colors (such as silver-white, dark gray, metallic colors, etc.) and textures. When combined with glass, it creates a rich visual effect and is suitable for different architectural styles (from modern simplicity to classical solemnity).

The Rigid Support Is Reliable

The profiles are mostly made of aluminum alloy (such as 6063-T5/T6) or steel. The cross-sectional design focuses on the resistance to bending and shearing (such as rectangular, I-shaped and other solid or hollow cross-sections), with a relatively thick wall thickness (≥3mm at key parts), which can maintain stability over large spans and reduce deformation.

The visible frame curtain wall profiles feature “visible structure, reliable force bearing and easy installation” as their core characteristics. While ensuring the safety and durability of buildings, they also take into account both decorative and economic aspects, making them a practical and universal choice in building curtain walls.

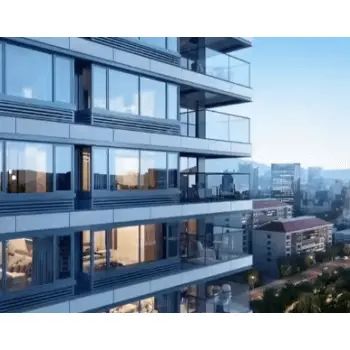

Window Wall

Window wall is a non-structural building envelope system that combines Windows and arch shoulder slabs and installs them between floor slabs to form the facade. Unlike curtain walls, it relies on the floor structure of the building as support, with each floor serving as a horizontal anchor.

The window wall is composed of an aluminum frame, insulating glass units and a fascia board, which is usually made of stone or metal, balancing transparency and insulation. This system allows for abundant natural light while combining thermal rest to enhance energy efficiency, which is crucial for modern green buildings.

Although not very suitable for extreme heights, window walls perform well in mid-to-high-rise structures, combining functionality with aesthetic appeal, making them a popular choice for residential and commercial buildings, aiming to achieve well-lit and energy-efficient designs.

Window wall is a structural form in architectural design that combines Windows with walls. It usually refers to a facade system that integrates large areas of glass with the wall structure, emphasizing transparency and visual connection with the outdoor environment.

High Light Transmittance

The proportion of glass is high, maximizing the introduction of natural light and weakening the visual boundary between the interior and exterior.

Structural Integration

The window and the wall support system (such as frames and beams) work in coordination to bear the force, combining both decorative and structural features.

Flexibility

The type of glass (such as Low-E low-emissivity glass, laminated glass) and the opening method (fixed, casement, sliding, etc.) can be adjusted according to the design requirements.

Window walls are a compromise choice that balances aesthetics, functionality and cost. They are widely used in modern architectural design, especially suitable for projects that pursue a sense of transparency but do not require curtain wall performance.

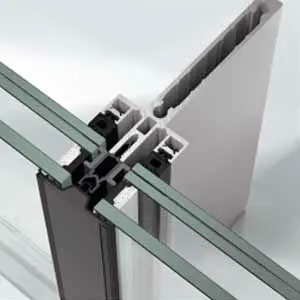

Pointed Supperted Curtain Wall

Point-supported glass curtain wall is a curtain wall system with point connection as its core. Its features are mainly reflected in structural form, visual effect, force application mode, etc., as follows:

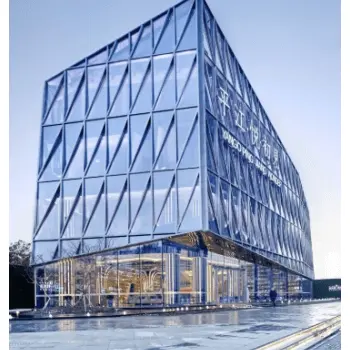

The VisualIs Transparent And Light

The glass panels are fixed by point-like connectors (such as stainless steel claws, bolts, etc.), with almost no exposed frame. When viewed from the outside of the building, there are only tiny connection points between the glasses, forming large areas of continuous transparent interfaces, minimizing the obstruction of the line of sight and achieving the lightness of “the building is glass”.

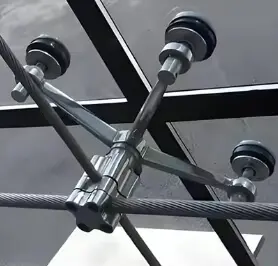

Point-type Force Transmission

The self-weight of the glass, wind loads, seismic forces, etc. are all transmitted to the hidden supporting structures (such as steel trusses, cables, steel columns, etc.) through discrete connection points. The force transmission paths are concentrated and clear, and the strength, stiffness and positional accuracy of each connection point are required to be extremely high.

High Technical Requirements And High Cost

High-strength glass, corrosion-resistant stainless steel connectors (such as 316 stainless steel), and precise support structures are required. Coupled with the high construction difficulty (professional teams are needed for calibration and positioning), the overall cost is usually higher than that of traditional frame curtain walls.

The Maintenance Convenience Is Moderate

The area of a single piece of glass is usually large. When replacing it, it needs to be hoisted by special equipment. However, as there is no frame to block it, cleaning and maintenance are relatively convenient, and it can keep the facade transparent and clean for a long time.

In conclusion, the point-supported glass curtain wall, with its core advantages of “ultimate transparency and exquisite structure”, is the preferred solution for modern architecture that pursues a distinctive appearance and high-quality spatial experience. It is particularly suitable as the facade system for landmark buildings, cultural buildings or high-end commercial buildings.

Unit Curtain Wall

Unitized curtain wall is a highly integrated prefabricated and assembled curtain wall system. Its characteristics are mainly reflected in structural form, construction method, performance and other aspects, as follows:

Factory Prefabrication Higher Precision

The frame, glass, sealing strips, insulation materials and other components of the curtain wall are pre-assembled into complete “unit panels” in the factory. Each unit can directly correspond to one bay or floor height of the building. The production process is completed in the workshop through precision equipment, and the dimensional error can be controlled at the millimeter level, which is much higher than the accuracy of on-site assembly.

The factory environment is stable, which can effectively avoid quality problems caused by weather conditions (such as rain, snow, and high temperatures) and differences in human operation during on-site construction, ensuring that the sealing performance, structural strength and other indicators of each unit are consistent.

Adapt To High-Level And Complex Projects

For super high-rise buildings or those with complex designs, unitized curtain walls can be constructed simultaneously in layers and areas, advancing in parallel with the progress of the main structure, significantly shortening the overall construction period. The prefabricated unit panels are directly hoisted to the preset positions on the building’s facade by tower cranes and other equipment, and then quickly fixed to the main structure through connecting parts, reducing on-site wet operations such as cutting and welding, and significantly improving construction efficiency.

The Structural Force Safety Is Strong

Each unit plate, as an independent load-bearing unit, is connected to the main structure of the building through dedicated connectors. It can effectively transfer its own weight, wind load, seismic load, etc. Moreover, the gap design between the units can absorb the displacement caused by building settlement and temperature deformation, reducing structural stress.

Easy To Maintain And with Low Later Costs

If a certain unit plate is damaged (such as broken glass or failed seal), it can be removed separately for replacement without large-scale disassembly, reducing the impact on the normal use of the building. The factory-prefabricated sealing system and anti-corrosion treatment (such as fluorocarbon spraying on the surface of profiles) are more stable, have a longer service life, and require less frequent maintenance in the later stage than traditional curtain walls.

In conclusion, unitized curtain walls, with their core advantages of “factory prefabrication, efficient installation, and reliable performance”, have become the mainstream choice for super high-rise buildings, large commercial complexes, and landmark buildings, especially performing outstandingly in projects with strict requirements for construction efficiency and building quality.

Glass Wall

As the core supporting structure of hidden-frame glass curtain walls, the design and performance of hidden-frame curtain wall profiles directly affect the safety, aesthetics and durability of the curtain wall.

No Exposed Frame

Hidden-frame curtain wall profiles fix the glass through structures hidden behind the glass (such as aluminum alloy profile frames, sealant joints, etc.). From the outside, the profile frames are almost invisible, only the glass panels and sealant joints can be seen, achieving a “panoramic” visual effect and greatly enhancing the transparency and modernity of the building.

Force Concealment

The force-bearing points of the profiles (such as the connection between the glass and the profiles, and the fixation of the profiles to the main structure) are all hidden on the inner side of the glass or inside the structure. It is necessary to ensure stability through precise mechanical calculations to avoid affecting the appearance or force imbalance due to exposed components.

Work in Harmony With Sealant

The groove design of the profile should provide sufficient bonding area for the structural adhesive (the adhesive width is usually ≥7mm) to ensure that the glass and the profile are firmly bonded through the adhesive joint. Meanwhile, the surface of the profile needs to undergo special treatment (such as chemical cleaning) to enhance compatibility with the adhesive and prevent the adhesive joint from falling off and causing water leakage.

The core feature of hidden-frame curtain wall profiles is “precision in concealment, safety in beauty”. Their design needs to balance mechanical properties, sealing performance, weather resistance and visual effect. They are widely used in high-end commercial buildings, office buildings, landmark buildings and other scenarios with high requirements for appearance and transparency. However, at the same time, its construction is difficult and costly, and the requirements for the quality of profiles, installation techniques and later maintenance are also stricter.